OUR SERVICES

At Upgrade Packaging, we offer cutting-edge packaging machinery and tailored solutions that empower businesses to scale efficiently, reduce wastage, and ensure product safety from factory to consumer. Whether you’re in food & beverage, pharmaceuticals, automotive, or consumer goods, we have the expertise and technology to streamline your packaging line.

- Semi Auto Strapping

- Automatic Strapping

- Carton Sealing

- Shrink Wrapping

- Stretch Wrapping

- Vacuum Packaging

- Pouch Sealing

- PET Strapping Tool

- Packaging Materials

- Download Brochure

SEMI -AUTOMATIC STRAPPING MACHINE

Our Semi Automatic Strapping Machine is designed for one touch easy operation, the instant heating method starts within 20 seconds with energy saving mode which automatically activates within 15 seconds of non – operation thus ensuring lesser breakdown and better longevity of the machine.

Lift type table-top option allows easy maintenance; intelligent controls in PCB can isolate malfunctioning and reduce time for repairs

Advantages/Features of Semi Automatic Strapping machine

-User Friendly , Easy apply Straps on Carton

-Ready to operate in a few seconds

-Heat Seals the straps

-High Quality Auto CutterLight in Weight

-Use less Space (Can accommodate anywhere)

SEMI AUTOMATIC STRAPPING MACHINE

HEAVY DUTY MODEL

| Strapping Force | 0-55 Kgf |

| Strap Width | 6-15 mm |

| Strapping Speed | 1.5 Sec / Strap |

| Min. Strapping Size | 60 mm(W) x 30 mm (H) |

| Max. Strapping Size | Not Stipulated |

| Machine Weight | 110 Kgs |

| Power Supply | 1 Phase, 220 V, 50 Hz, 350W |

| Machine Dimension (LxWxH) | 900mm x 580mm x 750mm |

SEMI AUTOMATIC STRAPPING MACHINE

REGULAR MODEL

| Strapping Force | 0-45 Kgf |

| Strap Width | 9-15 mm |

| Strapping Speed | 1.5 Sec / Strap |

| Min. Strapping Size | 60 mm(W) x 30 mm (H) |

| Max. Strapping Size | Not Stipulated |

| Machine Weight | 90 Kgs |

| Power Supply | 1 Phase, 220 V, 50 Hz, 320W |

| Machine Dimension (LxWxH) | 900mm x 580mm x 750mm |

SEMI AUTOMATIC STRAPPING MACHINE

LOWER TABLE

| Strapping Force | 0-55 Kgf |

| Strap Width | 6-15 mm |

| Strapping Speed | 1.5 Sec / Strap |

| Min. Strapping Size | 60 mm(W) x 30 mm (H) |

| Max. Strapping Size | Not Stipulated |

| Machine Weight | 110 Kgs |

| Power Supply | 1 Phase, 220 V, 50 Hz, 350W |

| Machine Dimension (LxWxH) | 11500mm x 580mm x 380mm |

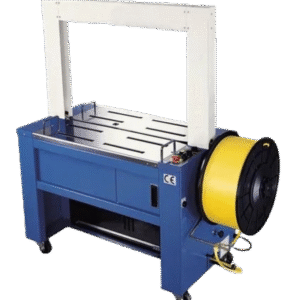

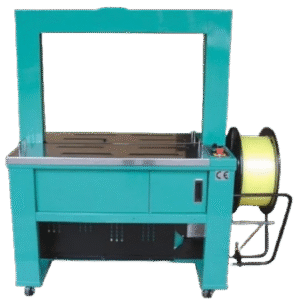

AUTOMATIC STRAPPING MACHINE

An Automatic Strapping Machine is used in packaging lines to apply plastic straps (typically polypropylene or polyester) around packages, boxes, or pallets to secure them for storage or shipment. It automates the strapping process, improving speed and consistency while reducing manual labor.

Advantages/Features of Automatic Strapping machine

Fully automatic operation: Detects the package and applies the strap without operator involvement.

High-speed performance: Can strap dozens of packages per minute depending on model.

Adjustable tension control: Ensures secure strapping without damaging the product.

Loop ejector / Jam prevention: Helps maintain smooth operation.

Compatible strap widths: Usually from 5 mm to 15 mm.

PLC controlled: Easy to adjust settings.

Arch size customization: To fit different package sizes.

AUTOMATIC STRAPPING MACHINE

REGULAR MODEL

| Arch Size | 850W x 600H mm |

| Power Supply | 3Φ, 380v, 50Hz, 1250 Watts |

| Strap Cycle Speed | 27 cycles per/min |

| Tension Strength | Max. 60 kgs |

| Strap Width | 9 / 12/15 mm |

| Sealing Method | Heat Sealing |

| Dimension | 1800W x 640D x 1275H mm |

| Table Height | 822mm |

| Machine Weight | 195 kgs |

| Control | PCB Controlled. |

AUTOMATIC STRAPPING MACHINE

HEAVY DUTY MODEL

| Arch Size | 800W x 600H mm |

| Power Supply | 3Φ, 380v, 50Hz, 1250 Watts |

| Strap Cycle Speed | 27 cycles per/min |

| Tension Strength | Max. 70kgs |

| Strap Width | 9 / 12/15 mm |

| Sealing Method | Heat Sealing |

| Dimension | 1800W x 640D x 1275H mm |

| Table Height | 805mm |

| Machine Weight | 220kgs |

| Control | PLC Controlled |

FULLY AUTOMATIC ONLINE

STRAPPING MACHINE

HEAVY DUTY MODEL

| Cycle Time | 2.5 sec/strap |

| Conveyor Speed | 21m/min(60Hz) |

| Layout Dimension | 1580 x 710 x 1538(mm) |

| Machine Weight | 286 Kgs |

| Power | 1kw |

| Power Supply | 3Φ, 380v, 50Hz, 1250 Watts |

| Reel Inside Diameter | 200 , 230 , 280 mm |

| Sealing Method | Heating element |

| Standard Arch Size | 850W x 600H |

| Strap Width | 9,12,15 mm |

| Table Height | 815mm |

| Tension Range | 15-70 kgs |

AUTOMATIC STRAPPING MACHINE

PNEUMATIC TOP PRESS

| Arch Size | 800W x 600H mm |

| Power Supply | 3Φ, 380v, 50Hz, 1250 Watts |

| Strap Cycle Speed | 27 cycles per/min |

| Tension Strength | Max. 70kgs |

| Strap Width | 9 / 12/15 mm |

| Sealing Method | Heat Sealing |

| Dimension | 1800W x 640D x 1275H mm |

| Table Height | 822mm |

| Machine Weight | 295 kgs |

| Control | PCB Controlled |

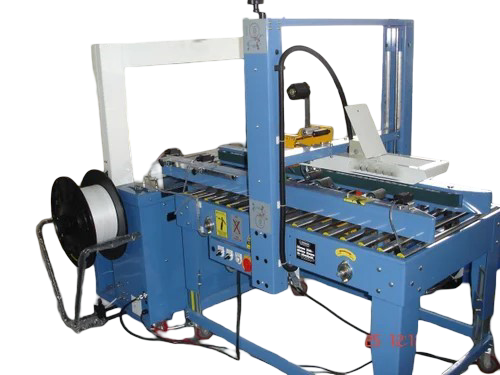

AUTOMATIC TAPING/STRAPPING

COMBO MACHINE

| Material | Mild Steel |

| Usage | Strapping/Taping |

| Conveying speed | 20M/per min (60Hz) |

| Strapping Speed | Approx. 24 st./Min |

| Polypropylene | 9, 12 or 15mm |

| Power Load | 230V/400V, 50/60Hz, 3PH, 1000 Watts |

| Weight | 360 kg |

| Tension Range | 15~70Kgs |

| Power Supply | 230V, 50/60Hz, |

| Tape Size | 48mm & 72mm |

| Min Carton Size(mm) | 150 x 150 x 150 |

| Max Carton Size(mm) | 900 x 500 x 500 |

Automatic Strapping Machine

LOWER TABLE MODEL

| Material | Mild Steel |

| Strapping Speed | Approx. 24 stps/Min |

| Polypropylene (PP) | 9mm/ 12mm / 15mm |

| Power Load | 415V, 50/60Hz, 3PH |

| Weight | 285kg |

| Tension Range | 15~70Kgs |

| Arch Size(mm) | 850W x 1000L, 1200L, 1400L |

| Material | PP Strap |

| Working Height | Low Table (450mm) |

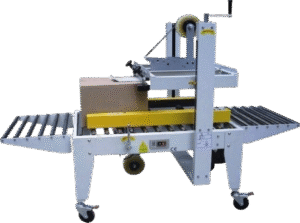

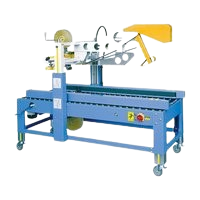

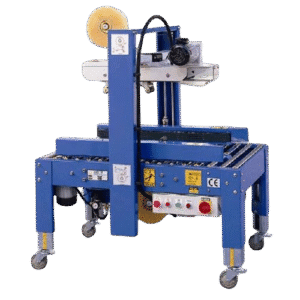

CARTON SEALING MACHINE

A carton taping machine or Carton Sealing Machine is an automated or semi-automated Packing Machine used to seal carton boxes with adhesive tape, typically in industrial or packaging settings. It helps streamline the packaging process by efficiently applying BOPP tape to both the top and bottom of cartons sealing the flaps in a uniform and consistent manner.

These machines come in various types, including side belt, top and bottom belt, and random case sealers, designed to handle different sizes of boxes. Carton taping machine enhances productivity by reducing packing time, reduce labour costs, and ensure secure and professional-looking packaging.

Advantages/Features of Carton Sealing machine

– Speed up Sealing Process

– Optimizes Tape Usage, reducing wastage

– Can handle various carton sizes with adjustable settings

– Can be integrated with conveyor system for seamless packaging process.

CARTON SEALING MACHINE

HEAVY DUTY MODEL

| Conveying Belt Speed | 20 mtrs. /min. |

| Size | Manual Adjustable H & W |

| Min. Carton Size | 150 (W) X (150) (H) X 150 (L) |

| Max. Carton Size | 500 (W) 500 (H) X No Bar |

| Power Supply | 1 Phase 220V 50Hz 300W |

| Working Height | 635mm~780mm |

| Width of Adhesive | 48 and 72 (mm) |

| Motor | Heavy Cooper Wind Motors |

| Machine Dimension | 1105(L) X 785(W) X (950~1420) |

| Weight | 155 kg |

| Drive | Side Drive and Top & Bottom Drive |

CARTON SEALING MACHINE

REGULAR MODEL

| Conveying Belt Speed | 20 mtrs. /min. |

| Size | Manual Adjustable Height & Width |

| Min. Carton Size(mm) | 150 X 150 X 150 |

| Max. Carton Size(mm) | 500 x 500 x No Bar |

| Power Supply | 1 Phase 220V 50Hz 300W |

| Working Height | 635mm~780mm |

| Width of Adhesive Tape | 48 and 72 (mm) |

| Machine Dimension | 1105 X 785 X (950~1420) (H) |

| Weight | 125 kg |

| Drive | Side Drive & Top & Bottom Drive |

CARTON SEALING MACHINE

AUTO FLAP CLOSER

| Power Supply | 1 Phase 110V/220V/240V |

| Packing Size (mm) | L 650 x W 500 x H 500 L 200 x W 150 x H 150 |

| Tape Width | 48 mm (2”) or 72 mm (3”) |

| Working Table H | 570~770 mm |

| Transmit Spd. | 20M / Min. |

| Air Comp. | 6 Kg / cm2 |

| Dimensions(mm) | L1290 x W950 x H1520 |

| Net Weight | 220kg |

| Drive | Side Drive |

CARTON SEALING MACHINE

RANDOM TAPING MACHINE

| Power Supply | 1 Phase 110V/220V/240V |

| Packing Size (mm) | L 650 x W 500 x H 500 L 200 x W 150 x H 150 |

| Tape Width | 48 mm (2”) or 72 mm (3”) |

| Working Table H | 570~770 mm |

| Transmit Spd. | 20M / Min. |

| Air Comp. | 6 Kg / cm2 |

| Dimensions(mm) | L1290 x W950 x H1520 |

| Net Weight | 220kg |

| Drive | Side Drive |

AUTOMATIC CARTON SEALING

RANDOM TAPING & AUTO FLAP CLOSER

| Power Supply | 1 Phase 110V/220V/240V |

| Packing Size (mm) | L 650 x W 500 x H 500 L 200 x W 150 x H 150 |

| Tape Width | 48 mm (2”) or 72 mm (3”) |

| Working Table H | 570~770 mm |

| Transmit Spd. | 20M / Min. |

| Air Comp. | 6 Kg / cm2 |

| Dimensions(mm) | L1990 x W950 x H1625 |

| Net Weight | 380 kg |

| Drive | Side Drive |

EDGE SEALING MACHINE

HEAVY DUTY MODEL

| Function | TOP/BOTTOM DRIVE |

| Power | 1 Phase, 220V/240V, 50HZ |

| Power Consumption | 1000W |

| Carton size | L320~800, W200~600, H180~60 |

| Tape width | 2″ or 3″ |

| Dimension | 2150 x 13650x 1580 |

| Speed | 5~10 carton/min. |

| Working table height | 650mm to 750mm |

| Compressed Air Requirement | 6 KG/cm2 |

| Weight | 550 Kg |

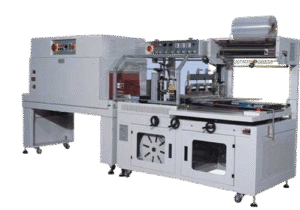

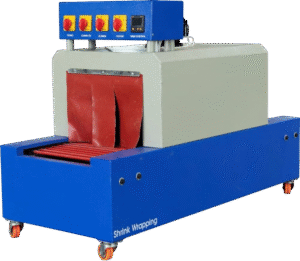

SHRINK WRAPPING MACHINE

A Shrink Wrapping Machine is a packaging device used to enclose products in a shrink film, which is then heated to tightly conform to the shape of the product. This machine is widely used in industries like food, beverages, electronics, pharmaceuticals, and retail for bundling and protecting items.

The process involves wrapping a product with a plastic film (usually PVC or polyolefin), which shrinks uniformly around the product when heat is applied through a heat tunnel or heat gun. Shrink wrapping not only offers a neat and tamper-evident finish but also protects items from dust, moisture, and damage during transportation.

Shrink wrapping machines come in various forms including L-bar sealers, chamber machines, and automatic shrink tunnels based on the scale and speed required.

Advantages/Features of Shrink Wrapping Machine

– Provides tamper-evident and secure packaging

– Enhances product presentation with a clean and glossy finish

– Protects items from moisture, dust, and scratches

– Can be used for bundling multiple items together

– Available in semi-automatic and fully automatic variants

– Suitable for various shapes and sizes of products

SHRINK TUNNEL

HEAVY DUTY MODEL

| Tunnel Size L xWx H | 1500 x 450 – 1000 x 200 – 500 |

| In feed Convey. | 850 (+ 50) |

| Sealing Temp. | 0-300* C |

| Packing Spd | 15-25 Pc/pr Min. |

| Net Weight | 500 Kgs |

| Power Supply | 3 Phase, 415 V, 50 Hz. 20 KwH |

| Fabrication | Heavy Structure powder coating |

| Conveyor plate | Roller Conveyor chrome |

| Film Used | PVC / PE |

| Cooling Tower | Dual Blower |

| Weight Capacity | Upto 80 kg |

| Heaters | SS, Spiral Heater |

AUTOMATIC SHRINK TUNNEL

L-Sealers

| Sealing Area | 450 X 550mm |

| Prdct. Pass thru H. | < 150mm |

| Max. Packing Size | < 500mm |

| Max. Packing Size (W+H) | < 430mm |

| Pkg Spd. | 15-25 Pc/pr Min. |

| Max. Film Width | 550mm |

| Sealing pltfm | Adj. with center seal |

| Sealing Material | POF/LDPE |

| Power Requirement | 220V / 1 Phase / 50-60 Hz / 2.5 Kwh |

| Air Pressure | 5.5 Kg/cm2 |

| Machine Dimension | 1685 X 828 X 1480 mm |

| Net Weight | 225 Kgs |

SEMI-AUTOMATIC

SLEEVE & SHRINK WRAPPING

| Machine Dimension | 1129 X 1305 X 1991 |

| Max. Packing Size | < 700 |

| Sealing Cutter Size | 700 |

| In feed Conveyor HxL | 850 (+ 50) X 1500 |

| Sealing Temp. | 0-300* C |

| Packing Speed | 3-6 |

| Net Weight | 300 Kgs |

| Power Supply | 3 Phase, 415 V, 50 Hz. 20 KwH |

| Compressed Air | 6.0 |

| Film Used | PVC / PE |

| Body | MS Powder Coated |

AUTOMATIC

SLEEVE & SHRINK WRAPPING

| Sealing Type | Sleeve Sealing |

| Power Supply | 380V/50-60HZ/3 Ph |

| Max Product Size | 420 x 300 x 300 |

| Packing Capacity | 1 – 15 Pks/min. |

| Film Type | Polyehtylene (PE) |

| Max Film Type(mm) | 630 X 280 |

| Power Consumption | MAX. 20KW |

| Tunnel Oven Size | 1800 x 700 x 400 |

| Conveyor Speed | Variable, 15 m/min. |

| Conveyor Size | Silicon Coated Rods |

| Working Height | 850-950 mm |

| Air Pressure | 0.5Mpa (5 Bar) |

| Sealing Knife | Teflon coated “U” knife |

| Main Ctrl Comp | Siemens PLC & touch |

LABEL SHRINK WRAPPING MACHINE

| Chamber opening | 150 x 350mm |

| Infeed Conveyor | 150 mm |

| Outfeed Conveyor | 150 mm |

| Chamber Length | 1500mm |

| Conveyor Width | 120mm |

| Power Required | 3 Phase, 440v, 14 Kwh. |

| Controller | Digital Temperature |

| Conveyor | Silicon Sleeve Roller |

| Body | Mild Steel |

| Speed | Variable Speed |

| Motor | AC Motor 1Hp |

| Heaters | SS Heaters 12 No’s |

NECK SHRINK WRAPPING MACHINE

| Machines Dimension | 1543 x 400 x 1300 |

| Tunnel Size | 1000 x 150 x 400 |

| Max packing size | 120 x 400 |

| Packing speed | 8000 to 12000 pcs / hrs |

| Power Required | 1 Phase, 220v, 4.5 KwH |

| Controller | Variable Temperature |

| Roller or Conveyor | Silicon Sleeve Roller Conveyor or SS Belt Conveyor |

| Body | SS/MS Body |

| Speed | Variable Speed |

SHRINK TUNNELS

SHRINK TUNNELS

| Model | BS-3020 A | BS-4525 A | BS-4535 A | BS-4535 LA |

|---|---|---|---|---|

| Voltage(V/Hz) | 380/50(3 phase) 220/60(3 phase) | 380/50(3 phase) 220/60(3 phase) | 380/50(3 phase) | 380/50(3 phase) |

| Power(kw) | 4.5 | 6.5 | 9.0 | 12 |

| Loading(kg) | 10 | 10 | 10 | 10 |

| Speed(m/min) | 0~10 | 0~10 | 0~10 | 0~10 |

| Tunnel Size | 900×300×(50~200) | 900×450×(50~250) | 1200×450×(50~350) | 1200×650×(50~350) |

| External Dimensions | 1200×550×1000 | 1200×550×1000 | 1500×550×1200 | 1500×650×1200 |

| Net Weight(kg) | 70 | 110 | 120 | 140 |

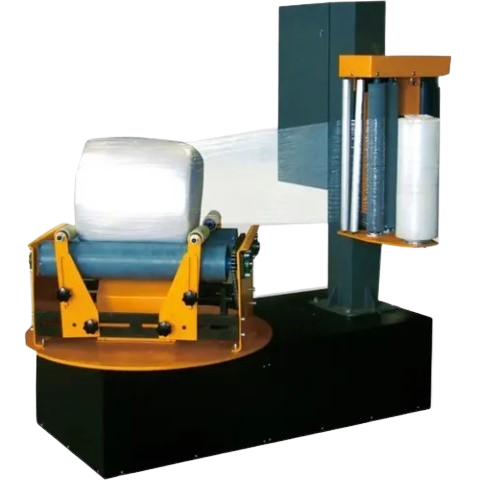

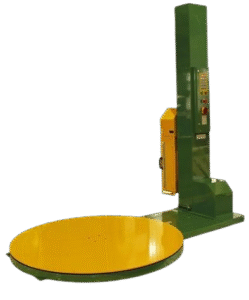

STRETCH WRAPPING MACHINE

A stretch wrapping machine is a device used to wrap products with stretch film to secure and

protect them for transport or storage. Stretch wrapping is widely used in various industries for

packaging Carton boxes, pallets etc. keeping them stable, dust-free, and tamper-resistant. The

stretch film is highly elastic, and when applied under tension, it clings tightly to the product, forming

a secure wrap.

Advantages/Features of Stretch Wrapping Machine

– User-friendly interface for quick operation

– Ensures tight and uniform film wrapping

– Reduces film wastage with adjustable tension

STRETCH WRAPPING MACHINE

BASIC MODEL

| Turntable | 500 X 500 mm |

| TT Speed | 3-20 RPM |

| Mast Height | 700 mm |

| Packing Height | 500 mm |

| Power Pre Stretch Unit | 0-300% |

| Min. Package Size | 250 x 250 x 250mm |

| Max. Package Size | 500 x 500 x 500mm |

| Weight Capacity | 100 Kgs (Max) |

| Power Consumption | 750W |

BOX STRETCH WRAPPING MACHINE

PNEUMATIC TOP PRESS

| Turntable | 500 X 500 mm |

| TT Speed | 3-20 RPM |

| Mast Height | 700 mm |

| Packing Height | 500 mm |

| Power Pre Stretch Unit | 0-300% |

| Min. Package Size | 200 x 200 x 200mm |

| Max. Package Size | 500 x 500 x 500mm |

| Weight Capacity | 100 Kgs (Max) |

| Power Consumption | 750W |

BOX STRETCH WRAPPING MACHINE

TOP MODEL

| Turntable | 400 X 400 mm |

| TT Speed | 3-20 RPM |

| Mast Height | 1000 mm |

| Packing Height | 900 mm |

| Power Pre Stretch Unit | 0-300% |

| Max. Package Size | 875 x 875 x 875mm |

| Weight Capacity | 100 Kgs (Max) |

| Power Consumption | 1 KWh |

| Operation | PLC Model |

| Film Used | Stretch film |

MINI REEL WRAPPING MACHINE

MODEL

| Wrap size(mm) | W(400-600)×L(200-650) |

| Power/voltage | 0.8kw/AC220V 50/60HZ 1P |

| Total weight | 250kg |

| Wrap efficiency | 20-40 Reels/Hour |

| Turntable speed | 0-12rpm |

| Film carriage | Power pre-Stretch system up to 300% with adjustable speed |

| Control system | PLC controlled |

| Packing material | LLDPE stretch film |

PALLET STRETCH WRAPPING MACHINE

TOP MODEL

PALLET STRETCH WRAPPING MACHINE

Machine Description

| Turntable | 1500 mm | Drive | AC motor |

| TT Speed | 3-15 RPM | Weight Capacity | Up to 2 MT |

| Mast Height | 2400 mm | Drive | AC motor |

| Max Packing Height | 2000 mm | 0~10 | |

| Power Pre Stretch Unit | 0-250% | Drive | AC motor |

| Power | 3 ph , 440 v | 2.0 kw | Power pre-Stretch system up to 300% with adjustable speed |

| Packing efficiency | 10-20 loads per/hrs | Depending up-on loads | PLC controlled, wrap layers adjustable |

VACUUM PACKAGING MACHINE

A vacuum packaging machine is a device used to remove air from a package and seal it tightly, often for preserving the freshness of food or protecting sensitive items. By eliminating air, the vacuum packaging process extends the shelf life of products, reduces the growth of bacteria and mold, and prevents oxidation.

Advantages/Features of Vacuum Packaging Machine

– Preserves freshness and prevents spoilage

– Strong and secure air-tight sealing

– Easy to operate and clean

VACUUM PACKAGING MACHINE

VERTICAL TYPE

| Model | DZQ 600L |

| Bag Position | Vertical |

| Voltage (V / Hz) | 3 Ph; 415V / 50 |

| Vacuum pump power | 750 |

| Sealing Power (W) | 800-1000 |

| Sealing Width (mm) | 10 |

| Lowest Pressure (KPa) | 1 |

| Sealing Position | 1 |

| Sealing Size | 1050 |

| Sealing Length | 600 x 10 |

| Air Charging (m3/h) | 20 x 1 Pumps |

| Vacuum Case | Stainless Steel |

| Dimension | 800 x 900 x 1700 |

| Weight (Kg) | 240 |

VACUUM PACKAGING MACHINE

TABLE TOP MODEL

| Model | DZ 400 | DZ 260 |

| Bag Position | Single Fiber Hull | Single Fiber Hull |

| Voltage | 1 Ph; 220V / 50 | 1 Ph; 220V / 50 |

| Pump power | 550 | 370 |

| Power | 500 | 400 |

| Width | 10 | 10 |

| LP (KPa) | 1 | 1 |

| Position | 2 | 1 |

| Sealing Size | 440 x 340 x 100 | 385 x 280 x 90 |

| Length | 400 | 260 |

| Air Charging | 20 | 10 |

| Case | Stainless Steel | Stainless Steel |

| Dimension | 550x485x600 | 480x330x340 |

| Weight (Kg) | 45 | 30 |

SINGLE CHAMBER

VACUUM PACKAGING MACHINES

DZ 500 MODEL

SINGLE CHAMBER VACUUM PACKAGING MACHINES

| Model | DZ 600 (Deep Chamber) | DZ 500 | DZ 400 |

|---|---|---|---|

| Chamber | Single Fiber Hull | Single Fiber Hull | Single Fiber Hull |

| Voltage (V / Hz) | 3 Ph; 380V / 50 | 1 Ph; 220V / 50 | 1 Ph; 220V / 50 |

| Vacuum pump power (W) | 1500 | 750 | 750 |

| Sealing Power (W) | 750 | 650 | 500 |

| Sealing Width (mm) | 10 | 10 | 10 |

| Lowest Pressure (KPa) | 1 | 1 | 1 |

| Sealing Position | 2 | 2 | 2 |

| Volume Chamber Bulk | 650 x 510 x 150 | 520 x 500 x 100 | 440 x 420 x 100 |

| Sealing Length (mm) | 600 | 500 | 400 |

| Air Charging Volume (m3/h) | 40 | 20 | 20 |

| Material for Vacuum Case | Stainless Steel (304) | Stainless Steel | Stainless Steel |

| Dimension (LxWxH) mm | 730 x 710 x 960 | 610x520x900 | 540x490x880 |

| Weight (Kg) | 160 | 140 | 120 |

DOUBLE CHAMBER

VACUUM PACKAGING MACHINES

DZ 500 MODEL

DOUBLE CHAMBER VACUUM PACKAGING MACHINES

| Model | DZ 700 | DZ 600 | DZ 500 |

|---|---|---|---|

| Chamber | Single Fiber Hull | Single Fiber Hull | Single (SS Hull) |

| Voltage (V / Hz) | 3 Ph; 380V / 50 | 1 Ph; 220V / 50 | 1 Ph; 220V / 50 |

| Vacuum pump power (W) | 1500 | 750 | 1500 |

| Sealing Power (W) | 1500 | 650 | 750 |

| Sealing Width (mm) | 10 | 10 | 10 |

| Lowest Pressure (KPa) | 1 | 1 | 1 |

| Sealing Position | 2 | 2 | 2 |

| Volume Chamber Bulk | 836 x 686 x 180 | 520 x 500 x 100 | 560 x 540 x 110 |

| Sealing Length (mm) | 700 | 600 | 500 |

| Air Charging Volume (m3/h) | 20 X 3 = 60 | 20 X 3 = 60 | 20 x 2 =40 |

| Material for Vacuum Case | Stainless Steel (304) | Stainless Steel | Stainless Steel |

| Dimension (LxWxH) mm | 1698 x 750 x 990 | 1450 x 610 x 860 | 1260x 610 x 850 |

| Weight (Kg) | 300 | 250 | 220 |

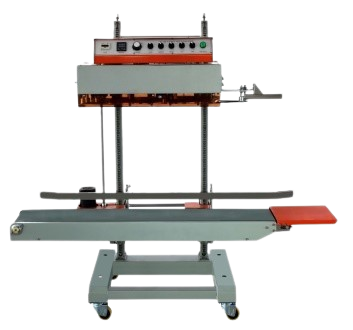

POUCH SEALING MACHINE

A Pouch Sealing Machine is a type of heat-sealing equipment used to seal the open edges of pre-filled plastic or laminated pouches. These machines are commonly used in the food, pharmaceutical, agriculture, and consumer goods industries to ensure airtight and secure packaging.

Pouch sealing machines use controlled heat and pressure to bond the layers of the pouch material, preventing leakage and contamination. They are available in various types such as hand-operated sealers, foot-operated sealers, continuous band sealers, and vacuum sealers — depending on the production scale and type of pouch.

Advantages/Features of Pouch Sealing Machine

– Ensures strong, leak-proof seals for various pouch types

– Helps preserve product freshness and quality

– Easy to operate and maintain

BAND SEALING MACHINE

VERTICAL & HORIZONTAL MODELS

| Power supply | 1 ph, 220V, 50Hz , 650W |

| Sealing speed | 0-10 Mtrs. Per/ Min. |

| Sealing Width | 8-10mm |

| Temperature Range | 0-200* C |

| Conveyor Size | 840mm X 180mm |

| Film thickness | < .8mm |

| Machine Dimension | 840 X 380 X 270 |

| Structure | SS & MS Powder Coated |

| Weight Capacity | 50 gms to 3 Kg |

BAND SEALER

HEAVY DUTY 5 Kg

| Power supply | 1 ph, 220V, 50Hz , 750W |

| Sealing speed | 0-10 Mtrs. Per/ Min |

| Sealing Width | 8-10mm |

| Temperature Range | 0-200* C |

| Conveyor Size | 840mm X 180mm |

| Film thickness | < .8mm |

| Machine Dimension | 840 X 380 X 350 |

| Structure | SS & MS Powder Coated |

| Weight Capacity | Up-to 5 Kg |

BAND SEALER

HEAVY DUTY 10 Kg

| Sealing type | Vertical Sealing |

| Body | MS powder Coated |

| Power supply | 1 ph, 220V, 50Hz , 1000 W |

| Sealing speed | 0-10 Mtrs. Per / Min. |

| Sealing Width | 8-10mm |

| Temperature Range | 0-300* C |

| Conveyor Size | 1100mm X 250mm |

| Conveyor Loading | 5 – 10 Kgs max. |

| Sealing Centre to Conveyor | 200-500mm |

BAND SEALER

HEAVY DUTY 20 Kg

| Power supply | 1 ph, 220V, 50Hz, 1250 W |

| Motor Power | 150 W |

| Sealing power | 550 W |

| Sealing speed | 0-12 Mtrs. / Min. |

| Sealing Width | 15 mm |

| Temperature Range | 0-400* C |

| Blower Fan | Heavy Blower Fan |

| Conveyor Size | 1520mm X 250mm |

| Conveyor Loading | 20 Kgs max |

| Sealing Centre to Conveyor | 100-700mm |

| Machine Dimensions | 1550 x 650 x 1550 |

PET STRAPPING TOOLS

PET Strapping Tools are specialized handheld or battery-operated devices used to tension, seal, and cut Polyethylene Terephthalate (PET) strapping around packages, pallets, or bundles. These tools are essential in industries like logistics, warehousing, construction, and manufacturing for securing heavy loads during storage and transit.

Advantages/Features of PET Strapping Tools

– Lightweight, durable, and easy to operate

– Provides high tension for securing heavy loads

– Available in manual, pneumatic, and battery-operated models

PET STRAPPING TOOL

PNEUMATIC MODEL

| Max tape thickness | 16 X 1mm |

| Max shrinking force | 259Kg |

| Dimension | 280 X 160 X 180mm |

| Weight | 3.8Kg |

| Average Air Pressure | 0.65pa |

| Strap Quality | PET Strap |

| Max Tension | 3500 NM |

| Joint Type | Friction Weld Sealing |

PET STRAPPING TOOL

BATTERY OPERATED

| Max tape thickness | 16 X 1mm |

| Strap Tension | 400 to 2000N |

| Dimension | 280 X 160 X 190mm |

| Weight | 3.9Kg |

| Shrinkage Speed | 260mm per/sec |

| Strap Quality | PET Strap |

| Joint Type | Friction Weld Sealing |

| Battery Service Life | Up-to 2000 Charging (Approx) |

| Battery Charge Time | 60 Mins |

PACKAGING MATERIALS

Common packaging materials include BOPP tapes, stretch films, shrink films, PET/PP strapping rolls, bubble wraps, corrugated boxes, thermocol sheets, poly bags, and corner protectors. Each material serves a specific function—whether it’s sealing, cushioning, bundling, or shielding goods.

Advantages/Features of Packaging Materials

– Protects products from physical damage, dust, and moisture

– Enhances shelf appeal and branding opportunities

– Available in various sizes, strengths, and forms

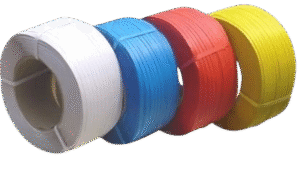

STRAPPING ROLLS

PACKAGING MATERIAL

| Size Available | 6mm to 15mm (Width) |

| Thickness | 0.5 to 0.8 mm |

| Roll Size | 6 Kgs to 12 Kg |

| Variant | Printed, Plain & Color Strap |

| Quality | Virgin White, Semi Virgin & Transparent |

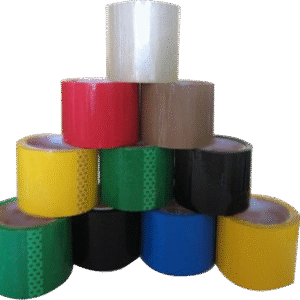

BOPP Self Adhesive Tape

PACKAGING MATERIAL

| Variant | Brown/Transparent/ Printed |

| Width | 48/60/72 mm |

| Length | 65 to 650 Mtrs. |

| Thickness | 38 to 54 Micron |

| Film | 23 & 29 Micron Film |

| Coating | 15 to 25 Micron Adhesive Coating |

STRETCH WRAPPING FILM

PACKAGING MATERIAL

| Size Available | 4” to 20” |

| Film thickness | 19 Micron to 51 Micron |

| Machine Grade | film Stretchability up-to 300% |

| Quality | Transparent & Super Clear |

POF SHRINK FILM

PACKAGING MATERIAL

| Size Available | 6” to 20” |

| Film thickness | 12 to 25 Micron |

| Fold | Centre Folded |

| Quality | Transparent Super Clear Quality |

| Length | Fixed Length |

LD SHRINK FILM

PACKAGING MATERIAL

| Size Available | 4” to 30” |

| Film thickness | 25 to 150 Micron |

| Form | Pouch and Roll Form |

| Variant | Transparent & Clear |

| Quality | Best Shrink Quality |

PET STRAP

PACKAGING MATERIAL

| Size Available | 9mm to 15mm |

| Thickness Available | 0.8 to 1.2 mm |

| Roll Size | 20 Kgs |

| Variant | Green Color Strap |

| Quality | Plain and Embossing |

DOWNLOAD BROCHURE

Get detailed information about our packaging machines, tools, and materials in one place. Download our brochure to explore product specifications, features, technical details, and application areas — designed to help you make the right packaging choice for your business.

What’s Inside the Brochure:

– Full product list with images

– Machine specifications and models

– Key features and benefits

– Application industries

– Available add-ons and accessories

– Contact information for inquiries

Ask for a Quote?

just fill the form. we will get back to you as soon as possible!